Plataine (Waltham, Mass., U.S.), a provider of AI-based mostly production optimization alternatives, has extended its cloud-based mostly automatic digital thread technology, to help producers doing the job with composite supplies mitigate present international provide chain troubles and enhance on-time shipping and delivery (see “Composites provide chain and manufacturing disruptions – how can AI and digitalization help?”).

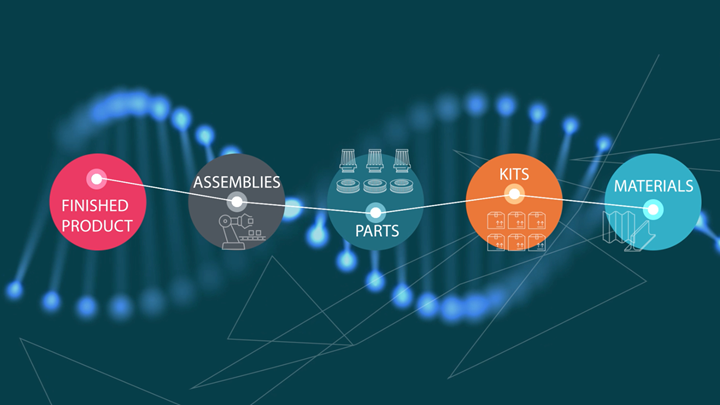

According to the corporation, the digital thread provides a holistic watch of an asset or material throughout its entire lifecycle. Its latest abilities use cloud-based engineering that enables producers to log the total genealogy of a products, stretching across many websites and businesses. Plataine claims this results in a holistic check out — from raw content to finished aspect — available to any one who has been provided with the credentials to entry the details.

Recent supply chain problems this kind of as soaring raw product and transportation charges, and acute shortages of labor and elements current unparalleled troubles to any maker. To mitigate this, Plataine states uncooked substance manufacturers can now make a “Digital ID” available for just about every content they deliver, enabling all suitable stakeholders in the offer chain to access any authorized data, together with product attributes, product background, shelf existence, problems and fault information. Aspect or assembly companies can now automate and speed up remember eventualities, cutting down scrap and increasing to start with-time top quality. Full traceability also implies that output flooring in very controlled industries, these kinds of as aerospace, are usually audit-ready.

In an period of labor shortages, method automation frees up workers for other, price-extra, jobs. Plataine’s technology is said to deliver automation where ever doable, from content obtaining, as a result of movement and consumption. A person distinct profit is automatic tracking of time-sensitive raw material, guaranteeing exposure time limits are not exceeded. All this removes prospective for human mistake, primary to diminished content waste, far better stock preparing, lowered re-perform and scrap.

“Our expanded electronic thread know-how permits producing businesses to securely share product and solution knowledge, and enables supervisors to know what is happening at all details together the offer chain and manufacturing traces,” Avner Ben-Bassat, president and CEO of Plataine, emphasizes. “We are enthusiastic to aid companies much better cope with the latest source chain difficulties, lower expenses and increase good quality regulate, while liberating overworked employees from mundane tasks.”

Plataine will be in attendance at SAMPE 2022 in Charlotte, N.C., from Might 23-26, booth #H24.