Showa Denko (SDK) (Tokyo: 4004) and Microwave Chemical

Co., Ltd. (Microwave Chemical) have started joint

improvement of a new microwave-dependent chemical recycling

technologies to straight rework utilized plastic into simple

chemical feedstock. The two firms are implementing

many ways to obtain carbon neutrality by 2050, and aim

to commercialize the new engineering before long.

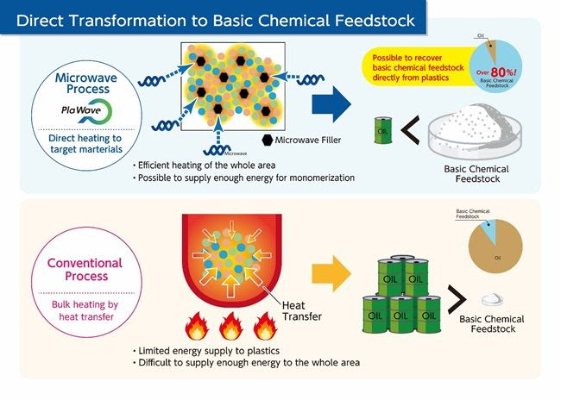

1: Comparison of microwave and conventional

methods

SDK and Microwave Chemical

will goal to create a engineering that decomposes made use of

plastic containers and packaging by irradiating microwave,

therefore developing standard chemical feedstock these types of as ethylene

and propylene. By the conclude of this yr, the two companies

will research conditions for development of product by way of

microwave heating, lookup for catalysts to improve the yield

of targeted parts, and test to improve ailments and

procedures for decomposition to create fundamental

engineering.

In the joint engineering progress, the

two providers will use microwave heating, a kind of electrical

heating utilised also in a microwave oven. When an item is

irradiated, microwave right influences dielectric substance,

resulting in internal heating, selective heating and swift

increase in temperature. In contrast with other heating techniques,

microwave heating is special in that it heats only the

item. In the prepared method, we will use microwave

absorber (filler) to give electrical power in a focused way to employed

plastic, enabling efficient decomposition of utilised plastic

into essential chemical feedstock. It will also lower electricity

intake for decomposition when compared with traditional

solutions. (Chart 1) Using advantage of such properties

of microwave heating, we will aim to change utilised plastic

specifically into standard chemical feedstock with small vitality

use and higher effectiveness.

SDK has been engaged

in chemical recycling operations due to the fact 2003 at its Kawasaki

Plant, producing thoroughly clean hydrogen and ammonia as a result of thermal

decomposition of utilised plastic. As a end result, SDK has

amassed over-all know-how about procurement of raw

elements, decomposition, and manufacture of final products.

(Chart 2) With its substantial-degree systems and deep

expertise in process progress, Microwave Chemical has the

functionality to scale up microwave systems. In the location

of chemical recycling, the organization has established

“PlaWave(TM),” a system of microwave-based plastic

decomposition technologies, therefore working with a variety of types

of plastic.

SDK and Microwave Chemical will get the job done

collectively to add towards achieving source preserving,

useful resource circulation and a carbon-neutral culture by way of

this joint

development.

© Scoop Media